Top Floor, Old Bank Building, Uxbridge Square, Menai Bridge, Anglesey - LL59 5WY

For properties not connected to the mains gas grid, the Off-Gas Hierarchy must be followed to determine the eligible heating measures under the Energy Company Obligation Scheme. In most cases, the priority measure should be selected based on this hierarchy. Only when certain circumstances make the priority measure unfeasible should lower priority options be considered.

First Priority Measures:

Air Source Heat Pump or Ground Source Heat Pump

Second Priority Measure:

Biomass Boiler

Third Priority Measures:

Replacement or Upgrade of Existing Electric Storage Heaters (ESH)

or Existing Electric Systems with New High Heat Retention Storage Heaters

A Measure is considered not feasible to install at each level of the hierarchy if::

It's Not reasonably Practicable: A measure is deemed reasonably practicable if it's technically applicable, according to the Retrofit Designer as Per PAS 2035:2019 requirements. It must also not result in an increase in energy bill when assessed against SAP for a home.

It Attracts an Exemption: Further details on exemptions can be found in paragraph 4.28.

It involves Biomass Heating, but the Premises Are not in a Rural Area: Biomass Measures are not suitable for non-rural areas.

For Level 3 Measures: If the home does not have a relevant pre-main heat source, the measure is not possible.

Recommendation Report: If one or more improvement Options Evaluation Reports are available for the premises and the measure is not among the recommended options in the most recent report, themeasure is not considered feasible.

For Home Without Improvement Options Reports: If no Improvement Options Evalution Report exists for the premises, but one or more Energy performance Cretificate (EPC) Recommendation Reports have been issued, and the measure is not among the recommended options in the most recent EPC report, it is not deemed feasible.

This refind version clearly outlines the order of priority fo heating measures for off-gas properties under the ECO scheme, along with the criteria for feasibility at each level.

Before a property can benefit from any heating and renewable measures under the current scheme regulations, there are certain prerequisites to ensure your home is well-prepared for energy efficiency upgrades. These requirements help create a more comfortable and energy-efficient living space.

Insulated Cavity Walls

If your property has cavity walls or extensions with cavities, they should be insulated to enhance energy efficiency. If your initial assessment shows uninsulated cavities, don’t worry—the ECO scheme covers the cost of cavity wall insulation, making it a seamless and cost-effective process.

Insulated Flat Roof

For properties with flat roof constructions, our initial assessment identifies any insulation gaps. If your flat roof lacks insulation, we will insulate it to meet the prerequisites for heating grants. The grant funding also covers the cost of insulating your flat roof, ensuring your home stays cozy and efficient.

Insulated Pitched Roofs

If your property features pitched roof constructions and the assessment reveals insufficient insulation, we will insulate these pitched roofs. This ensures that your home meets the requirements for obtaining heating grants. The cost of insulating the roof is included in the grant funding. We recognize that there are two types of pitched roofs: standard lofts (type one) and vaulted or sloping ceilings (type two)—see the diagram for further clarification.

Insulated Room In Roofs

Properties with room-in-roof constructions should also meet insulation requirements. If the assessment indicates a lack of insulation in any element of the room in the roof, we will insulate it to meet these prerequisites for heating grants. The cost of insulating the room in the roof is covered by our grant program. Refer to the diagram below to identify if your property has a room in the roof.

By addressing these prerequisites, your home will be better prepared for energy-efficient heating measures, creating a more comfortable and cost-effective living environment.

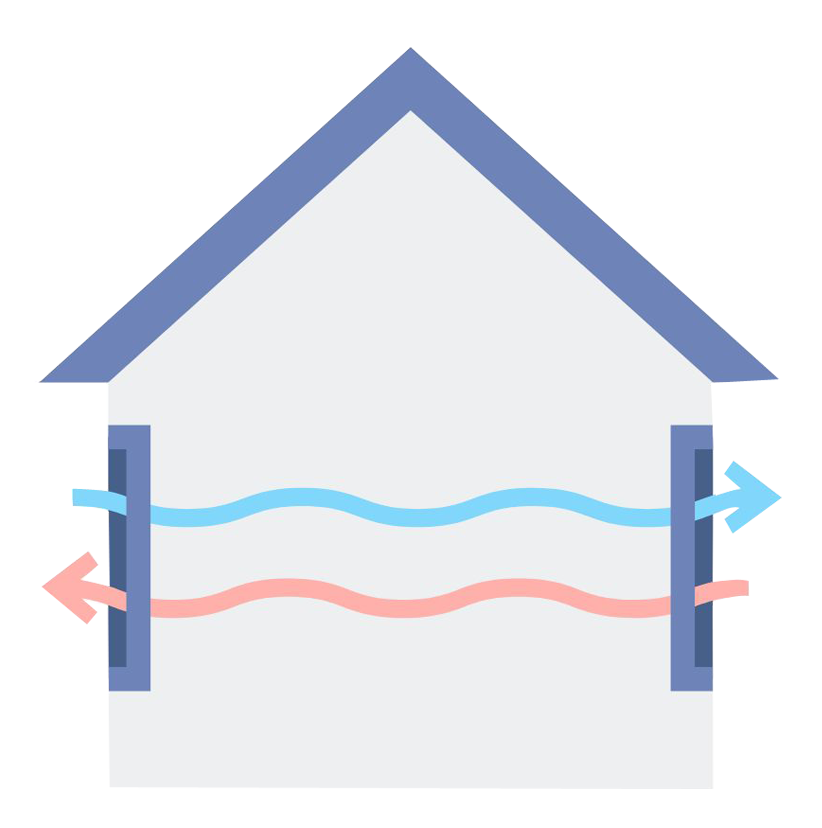

Ventilation is required in a dwelling when any type of fabric measure is installed (internal wall insulation, loft insulation, room in roof insulation, flat roof insulation, underfloor insulation and cavity wall insulation).

When any type of fabric measure is installed, it can alter the permeability of the dwelling and could invite issues to occur as a result. The main concerning issues are

Background ventilation

Background ventilation is a whole house ventilation system that allows the introduction of fresh outside air into a habitable room without opening a window. The purpose: To remove stale indoor air and replace it with fresh outside air.

This is achieved by installing trickle vents in windows or openable vents in external walls in all habitable rooms of a dwelling (bedrooms, dining rooms, living rooms, studies etc).

To support this, undercuts are also required on all internal doors leading from habitable rooms. An undercut will be deemed adequate if it is 10mm or larger (with some exceptions).

Combustion ventilation

Combustion air vents (core vents) provide a permanent (cannot be closed) supply of combustion air to rooms containing fuel-burning appliances which are not room-sealed.Rooms that require combustion ventilation are rooms with any of the following that are in use/could be used:

Extract ventilation

Extract ventilation to the outside of the dwelling should be provided in all wet rooms to extract moist or stale air from the room to the outside of the building. Wet rooms include the following spaces:

When installing any form of fabric measure in a property, if the property does not currently have any form of extractor fan in the wet rooms, we must install them in order to proceed with the project.

The two types of extract ventilators that are used alongside projects installing fabric measures are intermittent extract ventilators (IEVs) and decentralised mechanical extract ventilators (DMEVs).

When installing internal wall insulation, wet rooms are exempt from getting insulation due to the impracticality of removing fixed units to install the insulation systems. For wet rooms then we must:

Purge ventilation

Purge ventilation is manually controlled ventilation of rooms or spaces at a relatively high rate to rapidly dilute pollutants and/or water vapour and may be provided by natural means (for example, an openable window) or by mechanical means (for example, a fan).Many dwellingswill pass this aspect of ventilation. In some cases, habitable rooms that do not have openable windows, will need extractor fans installing in them.

Pulse testing

The pulse test is a type of air tightness testing method used to test the air permeability of a dwelling using compressed air. The pulse test system includes an air receiver and nozzle unit, and an air compressor unit and a control screen.

The air permeability of the house assesses how ‘leaky’ the house is. When a test is conducted in a dwelling, if the air permeability level is over 5m3/m2h, it means that the dwellings permeability is sufficient to not need trickle vents and undercuts installing when proposing to install fabric measures under ECO.

A pulse test will be required before and after any installs.

How is a test done?

01248 421044

We'd love to hear from you! Feel free to reach out anytime – your thoughts and questions are always welcome.

We Can Do